eco-infrared-heating-mats-under-ceramic-tiles-stone-surfaces-70w-m-230v-width-50cm-heat-decor

€19.68

€16.00

In stock

SKU

233

New generation Eco electrical Infrared Heating Mats

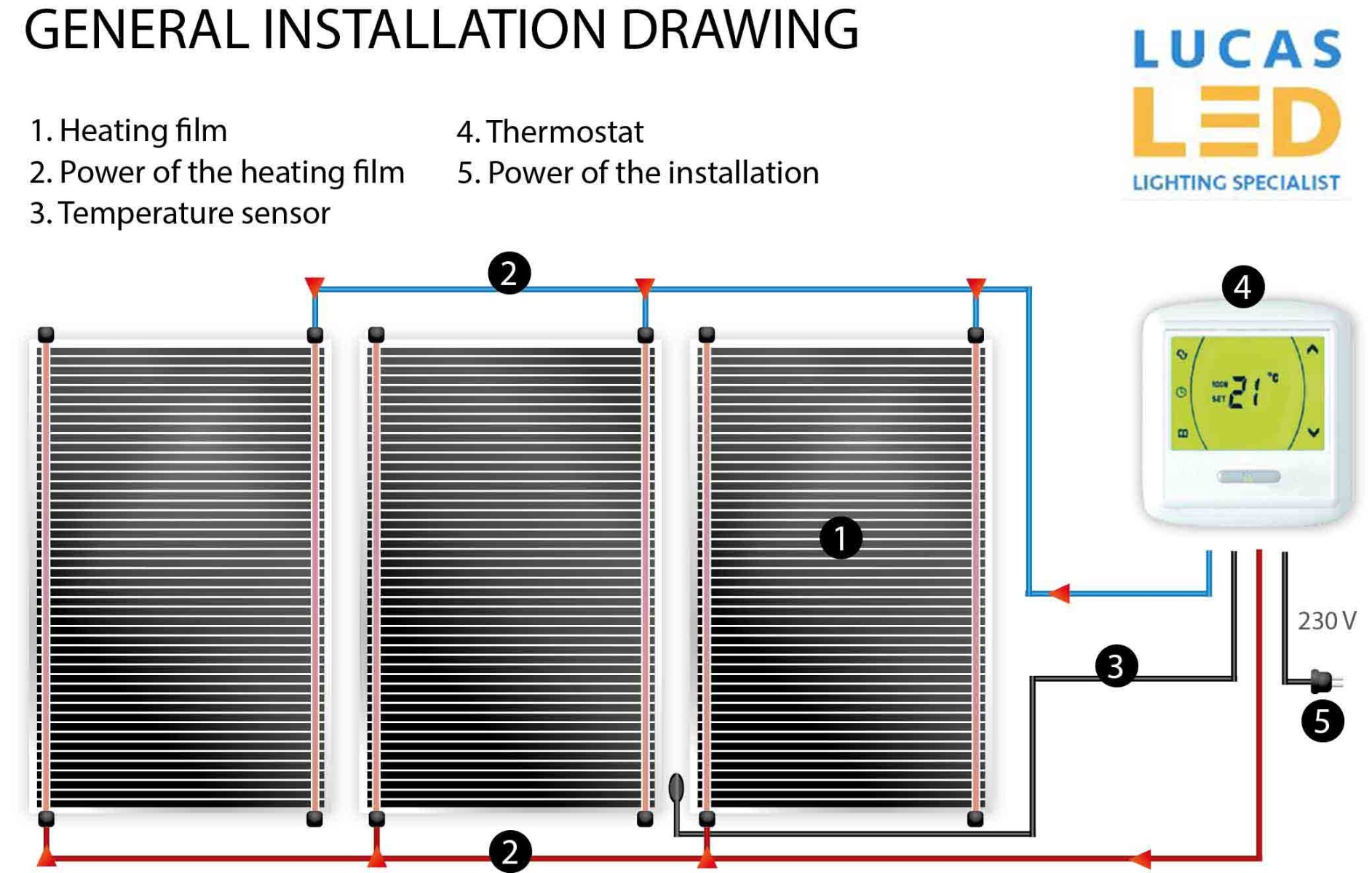

The Heat Decor heating film – 70 W/m with 50 cm width and 0.338 mm thickness is powered by 230 V electricity. It is distinguished by its electricity usage of 140 W/m2. It’s used to do floor heating and wall heating installations. It can be cut every 12,5 cm, only in the apposite places. The maximal temperature of the heating film is 40°C.

PRINCIPLES OF ACTION OF HEAT DECOR ‘s HEATING FILM

The Heat Decor heating film is powered by 230V electricity, which works based on the electrical resistance by emitting far infrared rays and far anionic rays. The heating system can be compared to the working of the sun rays which, just like the heating film, heat people and objects within its power range.

To every 1meter of heating film we give you 2,5m of Vapor Foil 0,2mm for free

for example:

When You buy 10m of heating film we will give You 25m Vapor foil 0.2mm with no charge !!

Price is per 1meter - 1m = 16,00e

We provide:

*Installation

*CUT to the lengths service if You require

We prepare varius lenghts with no extra charge. Just add Your sizes in comment or leave message to Us after order : [email protected]

Eco Infrared Heating film under ceramic tiles and stone surfaces for kitchen and bathroom (wet, damp room) , 70W/m, 230V, width 50cm

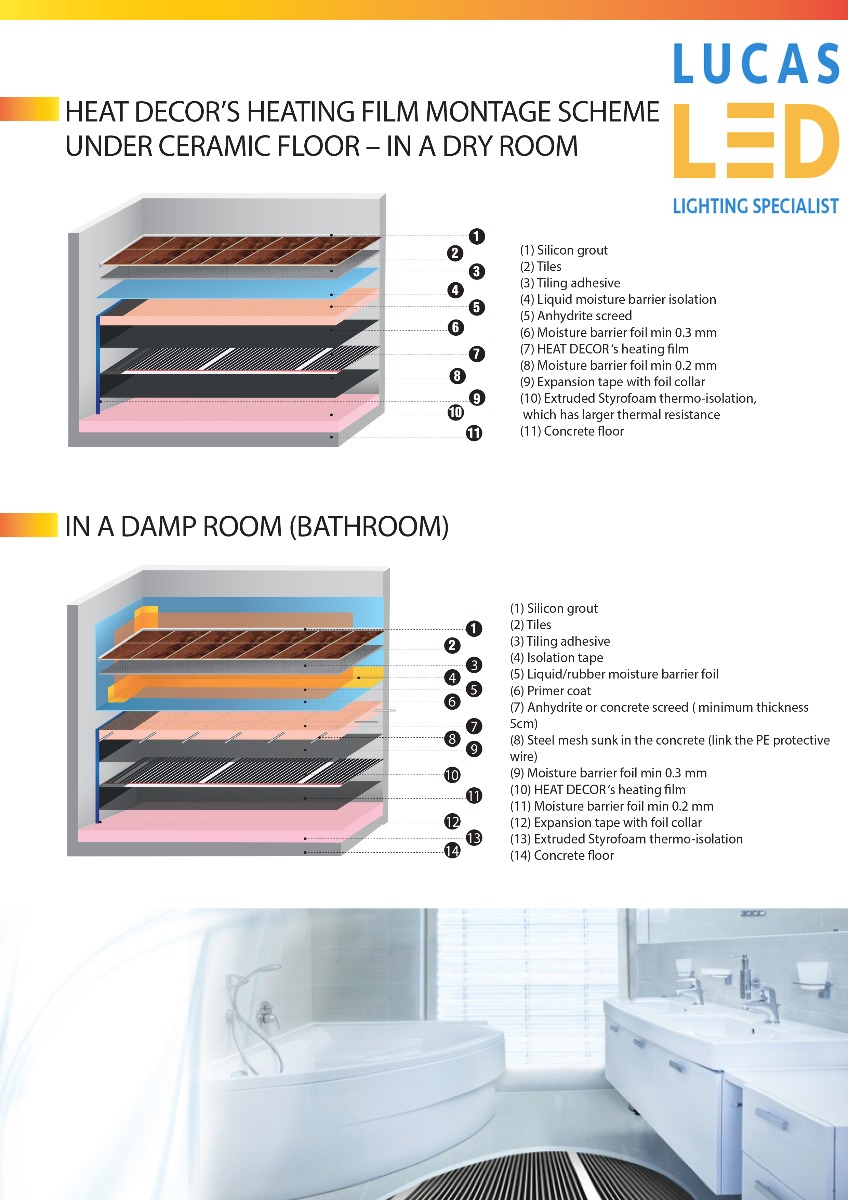

Floor heating with HeatDecor heating film (mats) drenched in anhydride screeding creates accumulation type of heating. Its the perfect way how to combine good temperature parameters of both technologies.

Practical Solution

Underflor heating technology with HeatDecor film drenched in anhydrite screeding, is realized by embedding the film into anhydrite self-leveling screeds. First, install HeatDecor heating fim and after checking whole system, it can be are drenched in anhydrite. For such prepared surface can be used any type of floor covering. With great thermal conductivity characteristics and accumulation property, the heat generated by the heating foil is quickly emitted into the surface and heats the floor as well as the entire space. Self-leveling properties ensure that the surface is smooth and you can place onto it right floor covering, which saves time and materials used. Anhydrite screed allows to create large heating surfaces up to 800 m2 without performing dilatation in screed thickness of 4 cm. This technology allows to continue further construction work cca 3 days after the implementation of the screed. After 7 days, you can turn on the underfloor heating system. Floor heating with Heat Decor heating film is ideal combination of thermal conductivity and anhydrite mechanical parameters of the floor.

Energy saving

The combination of heating film with anhydrite screed creates an accumulation type of heating, with the result that the heat is transferred into the room in long term. The heating system is fully automated with use of electronic programmable thermostat which significantly contributes to saving energy. Thanks to the programmable thermostat is possible to limit the maximum floor temperature as well as to regulate the temperature in the rooms. In case of ceramic or stone floor is level of heat accumulation significantly higher and the accumulated heat is longer time emitted into the room.

Thermal Comfort

HeatDecor heating film is technologically advanced product that meets all the requirements for simple functionality and practicality. With an ultra thin carbon heating film can be in your home, apartment or office eqipped by modern and environmentally friendly way of heating. Control is almost instantaneous and the entire system is fully automated so there is no need to worry about anything. HeatDecor film operates on the basis of the infrared radiation that positively stimulates the function of the human body. In addition, there is no undesired circulation of hot air and dust, which is particularly appreciated by allergy sufferers. Infrared heat is warming up directly all objects, walls, which has a positive effect and works and antifungal. Infra red heating film utilizes air as transport medium so there is no unnecessary losses in the heating process.

The heating film and operating costs

Monthly bill for this type of heating depends much on the overall thermal insulation of buildings, the materials used, the windows, and so on. In older buildings, or worse insulated places can increase costs.

To minimize costs, it is possible to combine floor heating with ceramic infra panels. The film is placed under the floor just on walking paths so you can feel comfortably warm floors and for walls can be used ceramic infra panels.

Advantages of underfloor heating with infrared heating film HeatDecor:

*Rapid warm up effect, low energy losses

*accumulation of the energy

*quick and easy regulation of the temperature at various times

*uniform distribution of heat in the heated space

*selective heating for specific areas

*easy installation

*the possibility of installing underfloor heating under any kind of floor

*low installation costs compared to other system

*maintenance-free and trouble-free

Heat Decor heating film is technologically advanced and economical product meeting all the requirements for modern heating systems.

Eco electrical HEATING FOIL (film, mats) HEAT DECOR HD 305G - 70W/m

- 50 CM WIDTH

- POWER 70W / mb, 140W / m2

- MAX TEMP. ~ 40 * C

- 230 V POWER SUPPLY

MODEL |

Power (watts)W/m |

WidthCm |

VoltageV |

Max.Tempof heating film*C |

Max.Lenght Installationof one heating filmM |

Max,Power Installationof one heating filmW |

Ticknessof heating filmmm |

CutlenghtCm |

HD305G |

70 Watts |

50cm |

230V |

~40 |

20 meters |

1400 Watts |

0,338mm |

12,5cm |

1- COPPER TAPE - acts as an electric conductor. We connect electrical wires supplying the heating foil to connectors using copper connectors.

2 - SILVER TAPE - fulfills the function of electrical connection of a copper strip with graphite paste.

3 - PET FOILS - these are components that connect all elements of a heating foil in a lamination process into one whole. PET films perform the protective function of the heating device against mechanical damage, penetration of water vapor and gases.

4 - GRAPHITE PASTE - is the basic heating material for the film. Occurs as a mixture of fine-grained particles whose main components are graphite and carbon. The proportion of graphite paste mixture is regulated by the heat power of Heat Decor foil.

5 - FILM CUTTING PLACE - is the area of the heating foil in which we can cut the heating foil to the desired size. This area is replicated every 12.5 cm.

Write Your Own Review